Basic Views

Climate change is caused by global warming and it is expected to give rise to abnormal weather and natural disaster. Therefore, the entire international society must unify to address this issue. In 2015, the 21st Conference of the Parties to the United Nations Framework Convention on Climate Change (COP21) was held in Paris and the Paris Agreement was adopted. In it, a global long-term goal of “limiting global warming to well below 2, preferably to 1.5 degrees Celsius, compared to pre-industrial levels” was announced.

Climate change is also likely to affect our Group’s business through a price increase in crude oil and raw materials. For these reasons, we will commit to the reduction of greenhouse gas (GHG) emissions with an understanding that addressing climate change is a critical issue for the sustainability of the world and our Group.

GHG Emissions Reduction Target

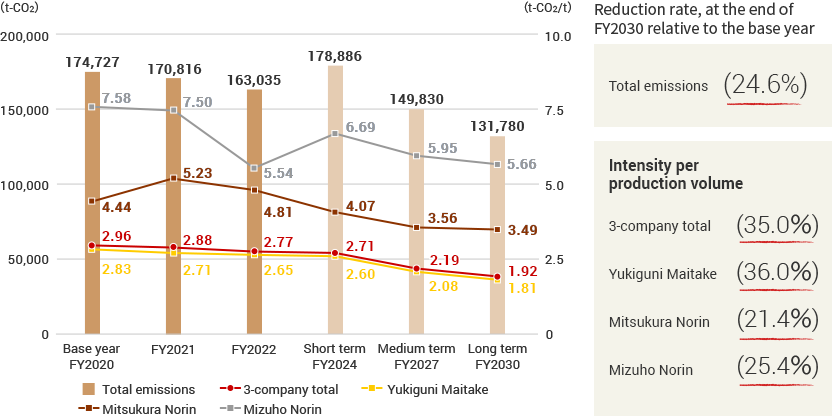

Our Group is promoting activities to reduce GHG emissions in order to mitigate risks related to climate change. We have started the measurement of GHG emissions (including scope 1, 2, and 3 emissions) since FY2021, and set a goal of reducing GHG emissions by 35% (compared to FY2020, based on emission intensity per production volume) by FY2030. In addition, with the ultimate target of net zero GHG emissions in FY2050, we will work to reduce the emissions throughout our value chain from procurement to production, logistics, and distribution.

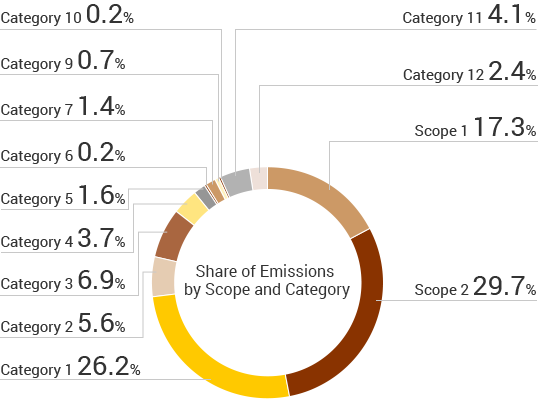

GHG Emissions by Scope (FY2022)

| Scope/Category | Emissions (t-CO2) |

Percentage | |||

|---|---|---|---|---|---|

| Scope 3 | Scopes 1 to 3 | ||||

| Emissions from supply chain | 163,035 | 100 | |||

| Scope 1 | 28,277 | 17.3 | |||

| Scope 2 | 48,489 | 29.7 | |||

| Category 1 | Purchased products and services | 42,639 | 49.4 | 26.2 | |

| Category 2 | Capital goods | 9,123 | 10.6 | 5.6 | |

| Category 3 | Fuel- and energy-related activities not included in Scopes 1 and 2 | 11,279 | 13.1 | 6.9 | |

| Category 4 | Fuel for upstream transportation and distribution | 5,968 | 6.9 | 3.7 | |

| Category 5 | Waste generated in operations | 2,633 | 3.1 | 1.6 | |

| Category 6 | Business travel | 309 | 0.4 | 0.2 | |

| Category 7 | Employee commuting | 2,353 | 2.7 | 1.4 | |

| Category 8 | Upstream leased assets | 0 | 0 | 0.0 | |

| Category 9 | Fuel for downstream transportation and distribution | 1,115 | 1.3 | 0.7 | |

| Category 10 | Processing of sold products | 271 | 0.3 | 0.2 | |

| Category 11 | Use of sold products | 6,691 | 7.8 | 4.1 | |

| Category 12 | Disposal of sold products | 3,888 | 4.5 | 2.4 | |

| Category 13 | Downstream leased assets | 0 | 0 | 0.0 | |

| Category 14 | Franchises | 0 | 0 | 0.0 | |

| Category 15 | Investments | 0 | 0 | 0.0 | |

| Scope 3 | 86,270 | 100 | 52.9 | ||

- * Covered entities: Yukiguni Maitake, Mitsukura Norin, and Mizuho Norin

- * Emission factors from IDEA (Inventory Database for Environmental Analysis) and the Ministry of the Environment were used. If no database exists, scenarios were created for calculation.

- * Yukiguni Maitake conducted an absorption-type merger of Mitsukura Norin (a wholly owned consolidated subsidiary) on April 1, 2023.

GHG Emissions Reduction Target

- * Yukiguni Maitake conducted an absorption-type merger of Mitsukura Norin (a wholly owned consolidated subsidiary) on April 1, 2023.

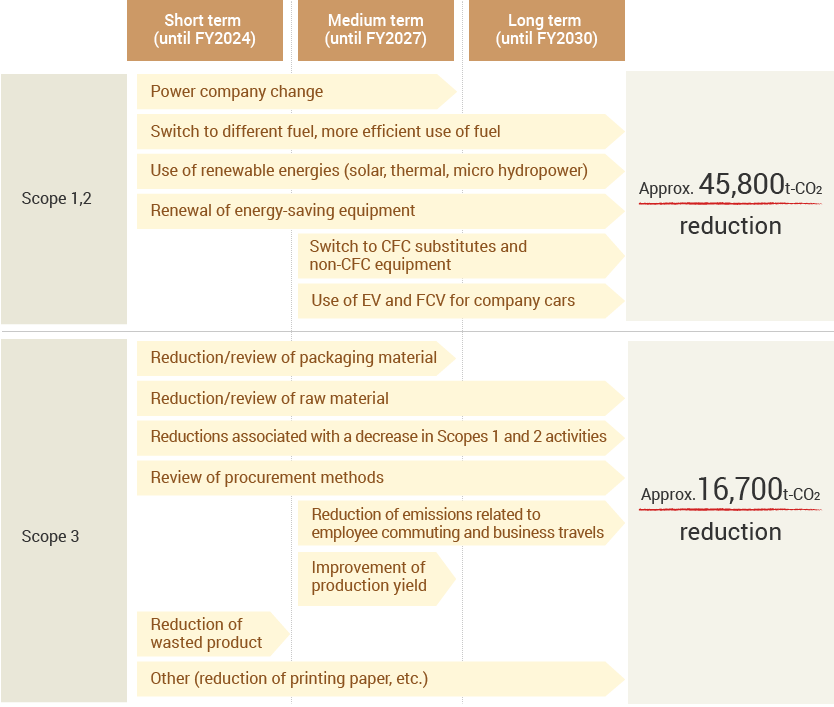

Roadmaps towards Our Goals

We have developed short-, medium-, and long-term roadmaps to achieve the FY2030 reduction target. By successfully implementing each program, we aim to reduce Scopes 1 and 2 emissions by approximately 45,800t-CO2 and Scope 3 emissions by approximately 16,700t-CO2. In addition, we will continue to explore and try new reduction programs using advanced technologies and innovations available in our society.

Key Initiatives

Procurement

Use of by-products for culture medium

For GHG emissions reduction and efficient use of natural resource, we utilize by-products such as sawdust generated from wood processing for construction or wheat bran produced in the flour milling process. The use of by-products contributes to the emissions reduction equivalent to 18,243t-CO2*.

- * Calculated for the base year (FY2020)

- * A by-product produced in the process of making a products is called a “reminder flow.” It is not allocated in IDEA (intensity database) calculation for GHG emissions, and its use contributes to the reduction of GHG emissions.

Production

Energy savings with LED lighting and ground water

In our mushroom cultivation facilities, we are working to save energy in cultivation processes by using energy-efficient LED lights and taking advantage of abundant ground water of the snowy region to control temperature and humidity inside cultivation rooms.

Use of biomass energy

We use sawdust that worked as culture medium for cultivation as a biomass boiler fuel. We reduce the use of fossil fuel significantly through the efficient use of renewable energy source.

Switch to LNG (Liquefied Natural Gas)

LNG (Liquefied Natural Gas) with low GHG emissions is used as fuel for the cultivation facilities. Following its introduction at the Gosen Bio Center in January 2021, it was introduced at the Bio Center 3 in October 2022. As a result, GHG emissions in Scope 1 for the fiscal year ended March 31, 2023 were reduced by approximately 13.1% at the Gosen Bio Center and approximately 10.8% at the Bio Center 3 compared to the previous year per production volume.

Logistics

Modal shift to railway transportation

Since 2017, we have been using railway transportation with refrigerated containers. This has contributed to 80% reduction in CO2 emissions compared to truck transportation.

Total logistics management to reduce truck deliveries

In 2021, Sales and Logistics Department was established for the total management from production to sales, inventories, and logistics to improve loading efficiency and optimize the number of trucks.

Office

Improvement of energy efficiency in head-office building

In Yukiguni Maitake’s head office in Minamiuonuma (Niigata Prefecture), renovation of the building, including a switch to LED lightings, was carried out in FY2020 to improve air conditioning efficiency. As a result, electricity consumption in the head-office building was reduced in FY2021 by 112,994kwh relative to FY2019.

We are exploring ways to improve energy efficiency in our Group companies’ offices as well.

Implementation of “Cool Biz” and “Warm Biz”

Since 2007, we have implemented a summer dress code (“Cool Biz”) and a winter dress code (“Warm Biz”) for all Group employees. Each employee can choose clothing according to room temperature all year round, including no neck ties. This helps to avoid extreme temperature settings of air conditioners and contributes to the reduction of electricity consumption in the office.

| Item | Yukiguni Maitake | Mitsukura Norin | Mizuho Norin | Group Total | |

|---|---|---|---|---|---|

| Total consumption | TJ | 2,827.3 | 64.6 | 284.4 | 3,176.3 |

| Intensity | TJ/t | 19.77 | 32.64 | 3.15 | 18.54 |

- * Total of A type heavy oil, gasoline, light oil, kerosene, LNG, LPG, sawdust boiler, and electricity

- * Yukiguni Maitake conducted an absorption-type merger of Mitsukura Norin (a wholly owned consolidated subsidiary) on April 1, 2023.