Basic approach

The Yukiguni Maitake Group will contribute to the realization of a sustainable society by reducing the environmental burden through the effective use and conservation of limited resources.

Initiatives to Reduce Waste

Utilization of culture media

For mushroom cultivation, culture media made from plant-derived materials, such as sawdust made by grinding wood and other materials, is used. At Yukiguni Maitake, we use the culture media after use as fuel for biomass boilers in order to reduce waste. By using waste culture media as fuel, the use of fossil fuels can be reduced. These initiatives therefore lead to a reduction in greenhouse gas emissions.

Lightweight trays

At Yukiguni Maitake, we have been working on reviewing our tray materials in order to contribute to waste reduction through the use of lightweight trays. In the fiscal year ended March 31, 2022, we realized a weight reduction of approximately 16% for the “Maitake Kiwami Tabekiri Pack” tray, 22% for the “Maitake Kiwami M Pack” tray, and 11% for the “Yukiguni Buna-shimeji W Pack” tray.

This means that a total of approximately 153.2 tons of plastic has been reduced in calculation*. In addition, in the fiscal year ended March 31, 2023, we also changed the materials of trays for products such as “Maitake Kiwami Happy Pack.” As a result, we realized a weight reduction of approximately 12% per tray.

- * Comparison of tray weights before and after the material change against the procurement volume for the year ended March 31, 2022.

Utilization of Recycled Trays

We use 100% recycled trays*1 for our mushroom products. We have confirmed that the raw materials used for our trays conform to the “Standard Specifications for Apparatus or Containers and Packaging Made of Synthetic Resins” and “Industry Voluntary Standards*2 ”, and thus, we are working to reduce environmental impact while ensuring food safety.

- *1. They include the reuse of scrap materials generated at plants manufacturing trays in addition to recycled raw materials generally collected.

- *2. They refer to the Center for Food Contact Material Safety, Japan Chemical Innovation and Inspection Institute, and the Positive List System for Apparatus and Containers/Packaging for Foods.

Reduction of Food Losses

We are working on the reduction of food losses. At our plants, we use the offcuts produced when cutting mushrooms for processed products such as boiled mushrooms in water . In addition, we have adopted packaging materials with high freshness retention in order to prevent waste during the distribution process.

All parts of most of the mushrooms produced by Yukiguni Maitake are edible. Therefore, almost no waste is generated by consumers, including households.

In order to ensure that our maitake mushrooms can be eaten up even more deliciously, their packages also contain the information that their stems are also edible and instructions on how to store them at home.

Relevant data

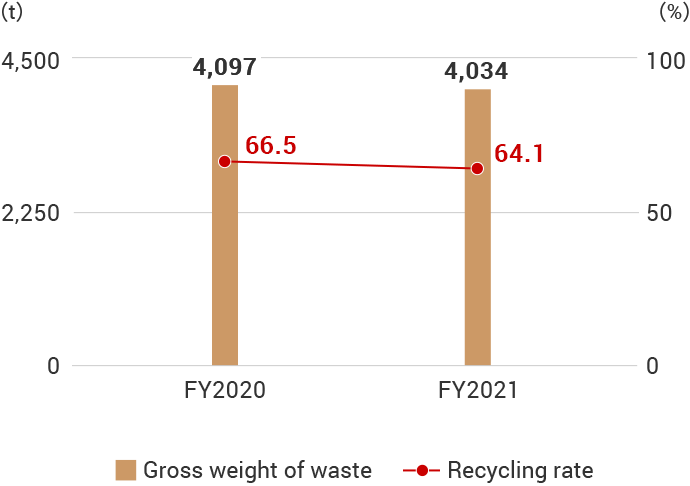

Recycling rate

Calculation method of recycling rate: Weight of recycled waste (t) / Weight of total waste (t) *100

- * Quantities are extracted from manifest data. Final disposal method is calculated from recycled waste.

Water resources conservation

Our domestic production plants are blessed with abundant water resources (groundwater) due to its location in snow country, and a circulation cycle in which the water is used for air conditioning and then returned to nature has been established. In addition, in our mushroom cultivation, we do not use any toxic substances that could lead to water pollution. Therefore, we believe that our current risk to water resources is low.

However, as a company that makes use of and nurtures the blessings of nature, water is an important resource, and therefore we consider that shortages of water resources or delays in responding to conservation of water resources will become our major risks. Going forward, we will continue appropriate water management in light of changes in the surrounding environment and developments in our business activities.

Efforts to Prevent Environmental Pollution

Control of Environmental Pollutants

We comply with laws and regulations related to the prevention of environmental pollution, and our Risk Management Committee establishes policies and measures related to environmental pollution risks for each fiscal year on an annual basis to implement ongoing management of wastewater, soot and smoke, CFCs (chlorofluorocarbons), waste, and others from our plants.

Air Pollution Prevention Initiatives

We are currently promoting the conversion of the fuel used in our cultivation centers to LNG (liquefied natural gas). LNG is a clean energy that contains almost no impurities. Therefore, in addition to producing less CO2, it also produces less NOx and does not produce SOx or soot and dusts.

Cultivation without the use of any pesticides or chemical fertilizers

All of our mushroom products are produced at facilities for cultivation and are free from any pesticides or chemical fertilizers, which are said to have a high environmental impact.